Look familiar?

by John Curnow, Sail-World.com AUS Editor 25 Sep 2024 23:00 BST

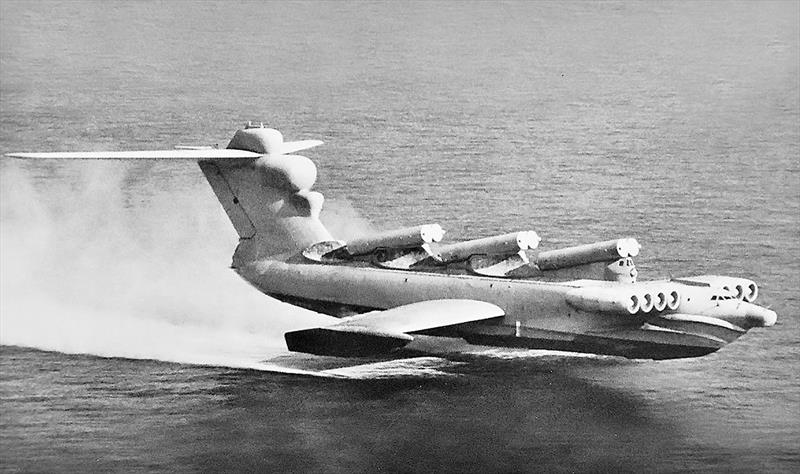

The Soviet Lun Class Ekranoplan was capable of just on 300 knots with a range of 1,000nm - it just needed flat water.. © USSR

OK. So the delivery system is different, to say nothing of the overall mission parameters, but the AC75 and the Soviet, Cold War era Lun-class Ekranoplan do both use ground effect. Both are designed to be combatants. Both get the job done with supreme efficacy. Both are also lighter than their conventional cousins. Both require definitively less horsepower than their relatives.

Yes. The parallels are most definitely there. There's a futuristic, decidedly martial and distinctly spaceship kind of look going on, especially if taken into consideration with your 'in-era' glasses on. Now it's a good thing the outcomes are virtually poles apart. One is just a step in the ladder up from the mighty Spruce Goose when it comes to 'flying' hours achieved. The other continues to make you more and more interested in the America's Cup and the advances in engineering that have brought it about.

Probably the most addictive aspect of AC75 racing is the bear away. Even more acceleration, and bucket loads of power. Time to be very gentle with the kit. Now as nice as all of the above is, this piece is actually about foils. The lift department in the mix. I mean they're super-visible, either up or down, and don't just do The 5th Dimension Up, Up and Away aspect of the equation. They're also there for righting moment.

Back in AC36 we looked at the sails, and I am very much obliged to all those who have helped me with the tech aspects for a lot of the material we publish. Previously, I have hinted that the foils might be something I would get my teeth into for AC37. Naval Architect, Andy Claughton, who is also the International Technical Committee Chairman of the ORC has kindly offered to be the overarching fountain of knowledge. Cheers and thank you, Andy.

So clearly the arms are OD, and the entire arm/wing packages have to be of a particular weight to perform the second of their primary functions. Long chord, high area foils get you airborne, but offer stupendous drag. Short chord ones are great when you are going, but not so great at delivering the initial component of The 5th Dimension, nor being shall we say, compliant, during manoeuvres.

So bigger sections will give you more area to have the required mass, but one of the key elements to ponder is that there is a bunch of high-tech engineering that has gone into all the gizmos that actuate the stuff. Did someone say, swan? Looks great on the outside, down below there's a lot of stuff happening to control the edges. Imagine a plane without ailerons, flaps, slats, spoilers, elevators and rudder? That particular kiwi ain't flying.

The wings have one long flap across the trailing edge of the wing, and this is controlled by the flight controller using battery power.

Also, look closely, and that nacelle in between the wings is where the real weight is being centred, as it is just about at the outermost extension when that particular foil is the windward one. If it was legal, and safe, I am sure that depleted Uranium would have been the chose material. The specific gravity would deliver a smaller profile, so again, less drag on offer. There is a reason it looks like the bulbous bow at the front of a ship.

Now long foils are more efficient the longer they get, just like a glider. For that matter, take on Boeing's venerable B-52, for the lower sections of an AC75 foil look very much like the entire aircraft (minus the jet pods and tail plane, but with added winglets) has been hung underneath the actuating arm. You might also offer Boeing's 787 Dreamliner into the mix due to it's all carbon structure...

"You want to take off, so you'd like a big wing, but once you've taken off, you'd like a tiny wing. So you're caught between the devil and the deep blue sea, and the penalty for falling off the foils, which gets more likely as you make the foil smaller, is distinct, and that's all she wrote," said Claughton.

"So if you slow down and you can't produce enough force to lift the boat out of the water at your max lift coefficient, you're going to have to start to float. And then once you've come off the foils, a big foil helps you get back on quicker. But as soon as you're back up there, you're thinking to yourself, 'God, these foils are too big', so it's an absolute balancing act with the choice of area."

"The other big thing is with that the design of these things is a bit like the problem with the aerodynamics on the Formula One wing, where they actually want the wing to deflect under load, and get closer to the ground. The issue with the hydrofoil is that you have the fixed element of the wing, and then you've got the flap at the trailing edge. Trying to engineer the flap to stay where you designed it as it starts to take load when you put the flap down is the critical element."

"Having it stay where you positioned it is crucial. In previous Cups they had complex engineering to do fancy things with the foil, but when they were actually sailing along the flap wasn't in the position they thought it was. They had the distance too far between the hinge points, and it was starting to bend. The engineering is the key, so you can be sure your foil stays as you designed it when it's carrying seven or eight tonnes of load. I think the basic hydrodynamic design is quite straightforward, but the engineering is a nightmare."

"You also have the problem of cavitation, and you kind of can't avoid it. The cavitation manifests itself by the fluid starting to boil because the low pressure on the upside is now so low that the water just turns to bubbles. It's a shocking thing when it happens. It makes you feel like your teeth are going to fall out. It's not a smooth thing. So you're always designing against this cavitation limit. Once you get into 52/53 knots, your foil is this close to cavitating all the time and that's why the bear away at the top mark is a big problem, because you just can't avoid going fast and there's way more chance of cavitation," added Claughton.

Having both foils down for some manoeuvres divides the load, and you can keep the boat flying through the turn by sharing the lift between the foils. Call it training wheels, but it is a good thing, because if you go low-rider, you're gone. Yes, using the Ekranoplan's ground effect notion is great, and like the deck-sweeper sail, you want to seal the gap between sail and deck, Thing with the hull though, is that you want to be close, but not touch down even a little bit, as that is slow and can set about a kind of death spiral. Obviously the skegs also help to mitigate any desire for the entire kit to perform re-entry. Clearly pitch control is the number one job when fully foiling. Derrrrrr. And that's why Flight Control is an art.

"This business of foiling is much more engineering than it is naval architecture, now. It's not only engineering of the structure of the foils and stuff, but you've also got to make super-efficient hydraulic valves, otherwise you're going to wear out your cyclists. So, you spend more of your time worrying about hydraulics than even the hydrodynamics. Then there's the whole business of the software. I would say the hydrodynamics of the foils is just 10 percent of the problem."

"The elevator/rudder is now even more crucial because of the forces generated by the main foils. It is having to operate not only as a rudder, but also as an elevator, which is an incredibly critical role when you take in the engineering aspects of that governing it, hydraulically powering it, and all the other aspects. It is simply quite immense."

"If you're racing one of these boats, you're just in the valley of death the whole time because there's nothing that you know is absolutely reliable. It is like you are with the prototype the whole time, and never get to the production model. The gear is incredibly complex, all the different systems have to work together, and everything is hugely expensive!"

Do you make a spare of something, even though it is a million pounds, in case something goes wrong, but you won't have the three-month lead time if it does turn to custard? Tough call. Add in the design and production quality control elements to it all, and it is the kind of stuff that will have you staring at the ceiling at 3am.

"Back in the day you might have had a sailing team of 35 and a design team of 10. Well, it's gone completely the other way now."

This sort of racing is right up there. Ponder the analogy of being in an F1 and slamming the brakes on at the 50m board before the corner. Most people would faint under the G forces. Same thing here. The manoeuvres would be past the average sailor, and that's what makes it intriguing. You can see what it takes to control a Moth. It is less obvious here with the AC75, but ever so real. A game of genuine jeopardy, me thinks.

OK. There it is. There is so much more on the group's websites for you. Simply use the search field, or 'edition' pull-down menu up the top on the right of the masthead to find it all. Please enjoy your yachting, stay safe, and thanks for tuning into Sail-World.com

John Curnow

Sail-World.com AUS Editor