| Laser 28 - Excellent example of this great design Hamble le rice |

|

| Rossiter Pintail Mortagne sur Gironde, near Bordeaux |

|

| Laser 140101 Tynemouth |

|

List classes of boat for sale |

Daggerboard repair |

Post Reply

|

Page <1234> |

| Author | |

Jack Sparrow

Really should get out more

Joined: 08 Feb 05 Location: United Kingdom Online Status: Offline Posts: 2965 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: Daggerboard repair Topic: Daggerboard repairPosted: 24 Apr 07 at 1:25pm |

|

Sounds fair enough.

|

|

|

|

Adam.s

Posting king

Joined: 28 Aug 06 Location: United Kingdom Online Status: Offline Posts: 122 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 24 Apr 07 at 12:21pm Posted: 24 Apr 07 at 12:21pm |

|

Thanks for all the advice i think im going to put two short metal rods one running parallel with the trailing edge and the another with the bottom of the board. Epoxy them in and epoxy the chunk to the main part of the board.

|

|

|

|

Ian29937

Far too distracted from work

Joined: 25 May 05 Online Status: Offline Posts: 409 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 24 Apr 07 at 12:11pm Posted: 24 Apr 07 at 12:11pm |

|

I've done something similar but using a stainless bike spoke (15p from a decent bike shop) bent into a u shape, epoxied into two holes drilled into the board and then packed out to shape with filler. Worked a treat and no risk of exposed sharp metal if the repair fails. Ian |

|

|

|

Jack Sparrow

Really should get out more

Joined: 08 Feb 05 Location: United Kingdom Online Status: Offline Posts: 2965 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 Apr 07 at 6:42pm Posted: 23 Apr 07 at 6:42pm |

|

I may be better to try and make a 'biscuit cut' as you won't have much board for a screw. You can use small nails but this has been unsatifactory for me.

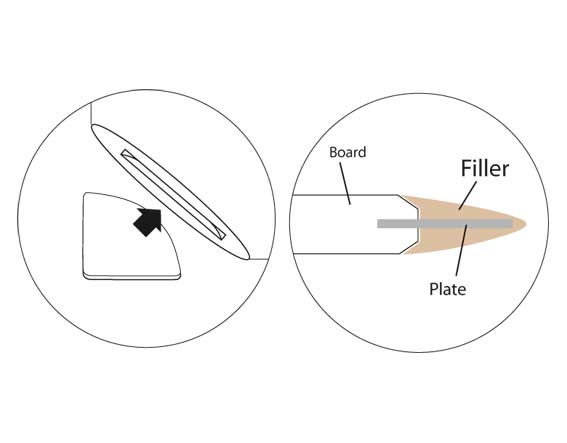

You'll need a small rotary blade. Fair the tip back to square. Cut the slot with the rotary blade. Stick in the plate ( either a bit of laminate glass or metal plate ). Let that go off. Sand back the 90 degree edge you have stuck the plate into so there is more contact area for the filler. You can even dill some holes in the plate for a better mechanical key fi you want. And then fill and fair. Finish with some spray paint if yoy feel like it.  |

|

|

|

Jack Sparrow

Really should get out more

Joined: 08 Feb 05 Location: United Kingdom Online Status: Offline Posts: 2965 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 Apr 07 at 6:01pm Posted: 23 Apr 07 at 6:01pm |

I'm suprised you haven't bled to death by now, I'd get down the hospital ASAP. Put the end of your thumb I can see in the picture inside tuperware box on top of a bag of frozen peas that should keep it fresh until the doctors can sew it back on! |

|

|

|

MRJP BUZZ 585

Really should get out more

Joined: 05 Mar 06 Location: United Kingdom Online Status: Offline Posts: 1496 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 Apr 07 at 5:40pm Posted: 23 Apr 07 at 5:40pm |

|

Do laser not have any specific rules about that?

|

|

|

|

mike ellis

Really should get out more

Joined: 30 Dec 05 Location: United Kingdom Online Status: Offline Posts: 2339 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 Apr 07 at 4:56pm Posted: 23 Apr 07 at 4:56pm |

|

yes the screw method does make it less likely to break off but it doesnt mean it wont. when i snapped the corner off at stokes bay in the winter (dry capsize was a little energetic and my left foot was a little too far back) i was a little suprised to find i had two self tappers sticking out the bottom of the obard and as i fell off it my drysuit caught and the left leg filled up with water and i found later i had a lovely deep cut in my shin. |

|

|

600 732, will call it Sticks and Stones when i get round to it.

Also International 14, 1318 |

|

|

|

redback

Really should get out more

Joined: 16 Mar 04 Location: Tunbridge Wells Online Status: Offline Posts: 1502 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 22 Apr 07 at 11:38pm Posted: 22 Apr 07 at 11:38pm |

|

If you lose the corner you can do the following. Drill a pilot hole and insert a screw partly into the main board. Cut off the head and build up the corner to the original shape, with car body filler. Sandpaper and paint. The screw reinforces the corner so that it is less likley to break off again.

|

|

|

|

radixon

Really should get out more

Joined: 27 Oct 06 Location: United Kingdom Online Status: Offline Posts: 2407 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 22 Apr 07 at 9:40pm Posted: 22 Apr 07 at 9:40pm |

|

I did the same thing to my Laser cb, I got told that what you can also do is carefully drill into both sections so you can fit a small metal dowel into both bits so it has more to grip to. My repair that I did has still survived many years later.

|

|

|

|

Strawberry

Really should get out more

Joined: 21 Jun 05 Location: United Kingdom Online Status: Offline Posts: 1337 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 22 Apr 07 at 8:16pm Posted: 22 Apr 07 at 8:16pm |

|

Buy some epoxy resin from your local chandlers. Something like this: Mix the epoxy with the hardner in the ratio according to the instructions. Be very precise with your amounts or it won't "go off". The best way to do this is with syringes. Mix into this some microfibres. Something like this: Mix in small amounts of microfibres until it is about the consistencty of toothpaste. Then use the mixture like glue to stick the two bits together. Use sandpaper to neaten it up. And Robert's your father's brother. Edited by Strawberry |

|

|

Cherub 2649 "Dangerous Strawberry

|

|

|

|

Post Reply

|

Page <1234> |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

Copyright ©2001-2010 Web Wiz

Change your personal settings, or read our privacy policy

Printable Version

Printable Version Delicious

Delicious Digg

Digg Facebook

Facebook Furl

Furl Google

Google MySpace

MySpace Newsvine

Newsvine reddit

reddit StumbleUpon

StumbleUpon Twitter

Twitter Windows Live

Windows Live Yahoo Bookmarks

Yahoo Bookmarks Topic Options

Topic Options

BUZZING IS FUN

BUZZING IS FUN  when i got home i took some sand paper to it and just filed the back to a smother shape. TBH you will hardly notice any performance difference with just a tiny nick out the back like that.

when i got home i took some sand paper to it and just filed the back to a smother shape. TBH you will hardly notice any performance difference with just a tiny nick out the back like that.