| Laser 140101 Tynemouth |

|

| Rossiter Pintail Mortagne sur Gironde, near Bordeaux |

|

| Laser 28 - Excellent example of this great design Hamble le rice |

|

List classes of boat for sale |

600, inside the hull, lots of rotten wood |

Post Reply

|

Page 123> |

| Author | |

mike ellis

Really should get out more

Joined: 30 Dec 05 Location: United Kingdom Online Status: Offline Posts: 2339 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: 600, inside the hull, lots of rotten wood Topic: 600, inside the hull, lots of rotten woodPosted: 06 Jan 09 at 6:22pm |

|

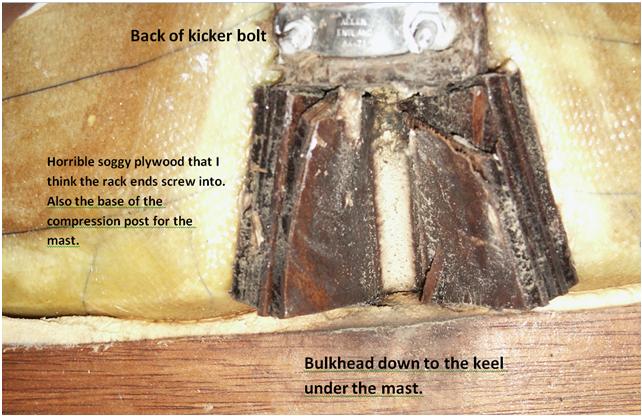

Right here's another one for you... What it shows is the inside of the hull under the mast. The plywood blocks used to attach the rack ends to the hull have gone horribly wet and are falling apart. The block with the kicker bolt in it is from what i can feel not much better but i can't get any pictures to prove it. So any ideas for the best way to get the horrible stuff out and how to replace it? |

|

|

600 732, will call it Sticks and Stones when i get round to it.

Also International 14, 1318 |

|

|

|

mike ellis

Really should get out more

Joined: 30 Dec 05 Location: United Kingdom Online Status: Offline Posts: 2339 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 06 Jan 09 at 6:33pm Posted: 06 Jan 09 at 6:33pm |

|

Ok heres some more picturrs of the mast post, I think the long piece of wood is ok, but the bottom piece is very damp. sorry it's fuzzy but i was just waving the camera around inside the hull hoping.

|

|

|

600 732, will call it Sticks and Stones when i get round to it.

Also International 14, 1318 |

|

|

|

JimC

Really should get out more

Joined: 17 May 04 Location: United Kingdom Online Status: Offline Posts: 6662 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 06 Jan 09 at 7:16pm Posted: 06 Jan 09 at 7:16pm |

|

Ouch!

Access is the killer with these jobs. The theory is simple enough: chisel out the rot, replace with new ply or probably better high density foam pads, reassemble. In practice the bits were probably all assembled with the hull split, and you won't be able to get at anything with acquiring treble jointed rubber arms... Have a chat to RS. If they have no good ideas we can discuss extreme measures, but they don't tend to look pretty afterwards. Edited by JimC |

|

|

|

craiggo

Really should get out more

Joined: 01 Apr 04 Location: United Kingdom Online Status: Offline Posts: 1810 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 06 Jan 09 at 10:48pm Posted: 06 Jan 09 at 10:48pm |

|

From memory those plywood pads only take the lateral wing loads, and they are shared with the rudder post anyway so its not terminal by any means.

The vertical load bearer is in the middle of that mess and is foam sandwhich and should be ok. As Jim says access is the problem here. You clearly have one hatch already, suggesting that the kicker bolt has been re-done at some point, so it may require you cutting a hatch in on the otherside so that you can get two arms in there. If you cant do the job through the bulkhead, I would think the only sensible answer is to take a section of the foredeck off, and then lap it back in once the repair is complete. Sounds bad but probably not too expensive a repair. As Jim says talk to LDC or Ashdown Marine before you get the jigsaw out. Paul |

|

|

|

mike ellis

Really should get out more

Joined: 30 Dec 05 Location: United Kingdom Online Status: Offline Posts: 2339 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 07 Jan 09 at 4:38pm Posted: 07 Jan 09 at 4:38pm |

|

yes the kicker bolt has been re-done once already, that was why i had the camera in the hull. I refitted the kicker bolt earlier in the summer when it went bang after a race. However the holes in the hull had worn a lot so it wasnt a very good seal. I was trying to estabilsh what was behind it so i could come up with a plan to make a better job of the repair. I shall now get on the phone to LDC. |

|

|

600 732, will call it Sticks and Stones when i get round to it.

Also International 14, 1318 |

|

|

|

Jimbob

Groupie

Joined: 05 Sep 06 Location: United Kingdom Online Status: Offline Posts: 77 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 08 Jan 09 at 12:07am Posted: 08 Jan 09 at 12:07am |

|

2 years ago when I fixed the kicker fitting, I found that the bolt ends went through the hull and a thickish piece of wood on the inside, which had worn down a bit and was damp due to leakage through the loose fitting. There was nothing else there. I did what you or whoever fixed your fitting did,ie I put a metal plate over the wood so I could tighten new locknuts hard against the plate, wood and hull.

I also replaced the mast foot 5 years ago which had been ground away by the metal plate and screws coming loose. I used epoxy filler to fill the screw holes and make up the foot and drilled new holes for the screws offset from the old holes. Then used gel coat filler to finish. I have had no problems with either of the two repairs since. Hope this helps |

|

|

Jimbob

|

|

|

|

Jamie600

Really should get out more

Joined: 14 Jun 05 Online Status: Offline Posts: 718 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 08 Jan 09 at 12:25pm Posted: 08 Jan 09 at 12:25pm |

|

Mike, Just offering a glass-half-full view; could the ply just be damp and peeling on the outer layer rather than rotten all the way through? Your boat hasn't fallen apart so it's probably OK, and perhaps not worth spending a fortune cutting the boat open and repairing it potentially for no reason. I'd get the boat in a garage with a heater and dehumidifier and get the boat fully dried out, and concentrate on getting it water tight to stop any further problems and then see how it goes.

Edited by Jamie600 |

|

|

RS600 1001

|

|

|

|

mike ellis

Really should get out more

Joined: 30 Dec 05 Location: United Kingdom Online Status: Offline Posts: 2339 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 08 Jan 09 at 5:21pm Posted: 08 Jan 09 at 5:21pm |

|

I'm working very hard on the watertight thing at the moment, that's the reason I've come across this. I called LDC today and they came up with what seems like a very sensible suggestion to get the wood off and replace it without making huge holes in any part of the boat. First mark up very carefully where all the current fittings are and how big and where the lumps of ply inside the hull are. Next carefully use a dremnel to get the glass fibre out from around the lumps of wood, but leaving some glass in where the wood is. Now use a large punch and a hammer to remove the old ply from the inside of the hull, then collect the pieces from inside the hull. After that it should be just a case of making up new ply/foam blocks to replace the old ones, position them, and fix them in place with epoxy and string through the hull until the epoxy sets. Finally, rebuild the holes around the edges of the wood that i took off earlier and replace the fittings. How does that sound to you lot? |

|

|

600 732, will call it Sticks and Stones when i get round to it.

Also International 14, 1318 |

|

|

|

JimC

Really should get out more

Joined: 17 May 04 Location: United Kingdom Online Status: Offline Posts: 6662 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 08 Jan 09 at 5:48pm Posted: 08 Jan 09 at 5:48pm |

It all depends on how good you are at not losing your temper whilst working inside a confined space etc... I can think of two qualified professions, one being a dentist: I'll leave the other to your imaginations... It sounds feasible given time and care and patience. |

|

|

|

Jimbob

Groupie

Joined: 05 Sep 06 Location: United Kingdom Online Status: Offline Posts: 77 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 08 Jan 09 at 5:53pm Posted: 08 Jan 09 at 5:53pm |

|

"How does that sound to you lot"

No way Jose! |

|

|

Jimbob

|

|

|

|

Post Reply

|

Page 123> |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

Copyright ©2001-2010 Web Wiz

Change your personal settings, or read our privacy policy

Printable Version

Printable Version Delicious

Delicious Digg

Digg Facebook

Facebook Furl

Furl Google

Google MySpace

MySpace Newsvine

Newsvine reddit

reddit StumbleUpon

StumbleUpon Twitter

Twitter Windows Live

Windows Live Yahoo Bookmarks

Yahoo Bookmarks Topic Options

Topic Options