How Sea Sure came to making the Firefly rudder stock

by Daniel Henderson, Sea Sure 26 Jul 2021 12:00 BST

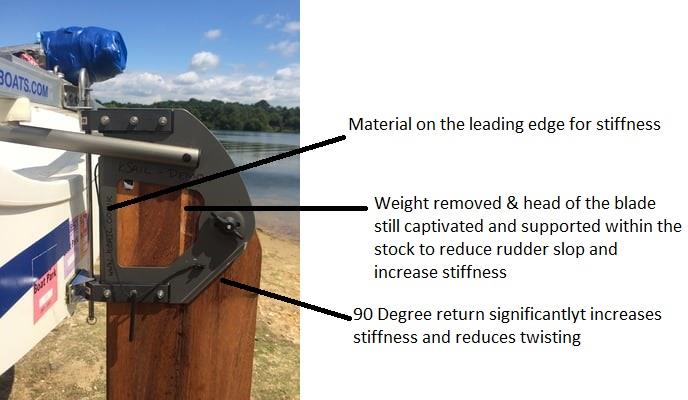

Sea Sure Firefly Rudder Stock © Sea Sure

For those of you that have tried your hand at Team Racing, you will know that those poor flights of Fireflys get put through a lot!

I would guess that a university or school owned Firefly in one year sees more use, crashes, breakages than what a privately owned club boat would see in 20. When we would travel and sail at a university team racing event it became quite normal to have to fix and bodge your boat back together again before the next race, and a lot of the time it was down to breakages with the rudder stock, tiller, or tiller extension. These breakages weren't necessarily down to a poor design or not being looked after, they were designed for fleet racing, where you try to use your rudder as little as possible to carry the most speed around the racetrack. Although the aim of team racing is to get around the racetrack in front of the other team, at times you are forced to carry out manoeuvrers that slow your competitors down to enable your team mate to catch up or overtake. This generally involves using the rudder as a hand brake which puts huge forces through the transom, stock, and rudder blade.

"When I joined Sea Sure I knew that the first product I would like to work on was the Firefly rudder stock", says Daniel Henderson, Sales Manager at Sea Sure Ltd. "It was a boat that we hadn't made a stock for and I felt that we could really make some improvements to the design, keep the cost down for the Universities and Schools, and make the overall experience at events better by people having less breakages".

At this point it was great to get a call from Keith Sammons of "K Sail" who was running a lot of the BUSA team racing events at the time. Keith expressed interest in being part of our design and evaluation process. This connection turned out to be key in the success of the firefly stock as Keith works with a large percentage of the schools and universities and knew far more about the finer details of firefly's as he was rebuilding them most days of the week.

Above is a 3D CAD video of our Sea Sure firefly stock. For us it is key to have material running between the top and bottom pintles/gudgeons as there is a huge amount of force and torque that gets put into this part of the stock. We have removed material from the centre of the stock to reduce the overall weight, but we have done this without compensating on stiffness as the head of the rudder blade is still supported well within the stock.

Keith Sammons of kSail:

At a team racing event we will frequently run over 100 races in a day; the reliability of the boats is therefore key to the success of the event. At kSail we have taken care to build a catalogue of equipment that is able to withstand the demands of the team racing environment while also affordable within hard pressed club, school and university budgets.

Our initial call with Dan was intended to see whether we could fit something from the wider Sea Sure range to the Firefly; that Dan had already started drawing something specifically for the Firefly was a huge bonus. We worked closely with Dan to develop and tweak the design. It was important to us that the new stock would be one hundred percent compatible with equipment already in use; therefore, we made sure the design fitted the standard Rondar gudgeon positions, rudder blade and more. Together with Sea Sure, we ran extensive pre-production trials which allowed us the chance to tweak and amend the initial design.

Since going into production, we have seen a gradual increase in take up as fleet managers recognise the cost and reliability benefits of the stock. The new stock has also enabled some additional improvements to be made to equipment elsewhere too - we have been able to produce a heavy-duty rudder blade which is more suited to institutions where users may not be quite so careful of the rudder tips when launching and recovering!