| Laser 140101 Tynemouth |

|

| Laser 28 - Excellent example of this great design Hamble le rice |

|

| Rossiter Pintail Mortagne sur Gironde, near Bordeaux |

|

List classes of boat for sale |

Tips for fitting out a new boat. |

Post Reply

|

Page 12> |

| Author | |

MattTrinder

Newbie

Joined: 19 Dec 11 Online Status: Offline Posts: 27 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: Tips for fitting out a new boat. Topic: Tips for fitting out a new boat.Posted: 27 Jan 13 at 4:26pm |

|

Sikaflex 291 is polyurethane, rather than silicon, and is specifically designed for marine use so should be fine.

|

|

|

|

E.J.

Posting king

Joined: 19 Feb 06 Online Status: Offline Posts: 184 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 27 Jan 13 at 11:28am Posted: 27 Jan 13 at 11:28am |

|

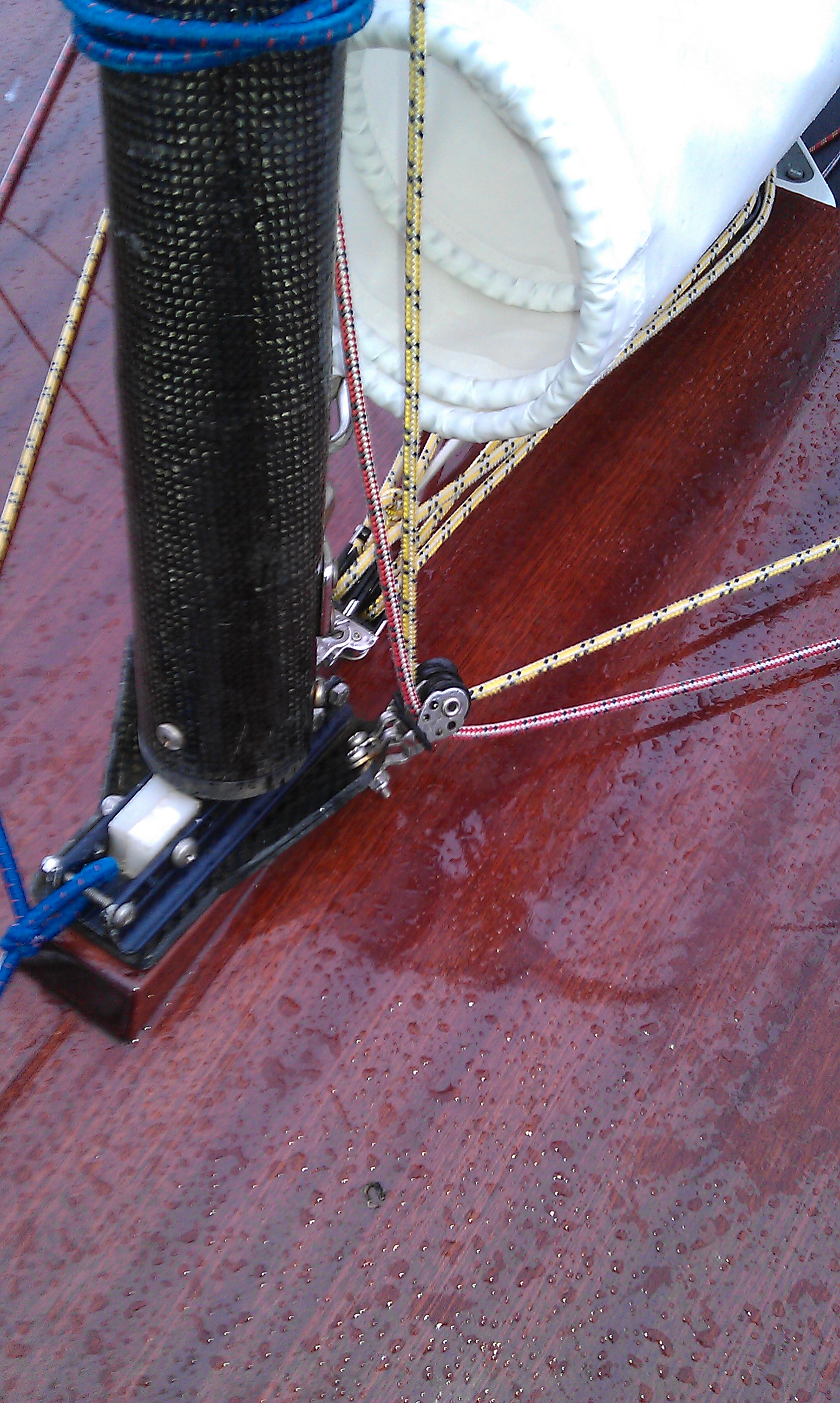

Its really simple, just a Carbon plate with angled flanges so I can attach 2 small blocks on each side and avoid having to fix them to the deck. The Mast step will sit on top of the flat portion in the middle. In terms of neatness; trial and error. I made a mould from cut tiles that I could clamp tightly, then when it had set I hacksawed it into the general shape I wanted and wet and dryed it to smooth the edges, I finished it with a final thin coat of epoxy to cover up the obvious amateur nature of it , and polished it up. I'm quite happy with it but on closer inspection you can tell it was made in a shed rather than a factory! the finish is a bit uneven.

The idea is to end up with something like this.  Edited by E.J. - 27 Jan 13 at 11:31am |

|

|

|

MerlinMags

Admin Group

Joined: 19 Mar 04 Location: UK, Guildford Online Status: Offline Posts: 589 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 27 Jan 13 at 7:59am Posted: 27 Jan 13 at 7:59am |

|

Would be interested to see the mast plate. What is it made from, and how did you made the edges neat?

|

|

|

|

E.J.

Posting king

Joined: 19 Feb 06 Online Status: Offline Posts: 184 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 11:15pm Posted: 26 Jan 13 at 11:15pm |

|

I'll have a hard job adding picture I don't have the boat yet.

|

|

|

|

RichTea

Far too distracted from work

Joined: 22 Jan 13 Online Status: Offline Posts: 207 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 10:25pm Posted: 26 Jan 13 at 10:25pm |

|

I think you should look for the pimp tread, that will give you inspiration when the 300 boys were about.

Are you going to pro grip, if so what colour. Oh and this thread is useless without pics

|

|

|

|

E.J.

Posting king

Joined: 19 Feb 06 Online Status: Offline Posts: 184 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 9:45pm Posted: 26 Jan 13 at 9:45pm |

|

Matt Trinder I was intending to seal with sikaflex 291, when you say don't use silicon does this qualify, if not what would you recomend?

|

|

|

|

E.J.

Posting king

Joined: 19 Feb 06 Online Status: Offline Posts: 184 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 9:16pm Posted: 26 Jan 13 at 9:16pm |

|

It is a Contender; from CServe. Funnily enough I have just made the mast base plate myself, looks good and saves me 8 holes.

I'm happy with the locations of the fittings now; its much the same as everyone elses, I was more after tips to make it a nice job.

Incidently, how do you all judge what bit size to use on screws when dealing with epoxy, is it the shank width, as with poly/vinylester or is there more to consider? Edited by E.J. - 26 Jan 13 at 9:17pm |

|

|

|

mongrel

Far too distracted from work

Joined: 27 Aug 08 Online Status: Offline Posts: 304 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 5:52pm Posted: 26 Jan 13 at 5:52pm |

If it is a Contender, I would look at getingt one of those carbon mast foots, that the Germans use, with the wings for the blocks for downhaul & outhaul, save drilling a few holes in the hull. Edited by mongrel - 26 Jan 13 at 5:54pm |

|

|

|

MattTrinder

Newbie

Joined: 19 Dec 11 Online Status: Offline Posts: 27 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 5:42pm Posted: 26 Jan 13 at 5:42pm |

|

Don't seal/fix fittings with silicon. And don't use 3M 5200 if you ever want to get things off again without destroying the Gelcoat.

|

|

|

|

Rob.e

Really should get out more

Joined: 19 Oct 04 Location: United Kingdom Online Status: Offline Posts: 545 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 26 Jan 13 at 5:39pm Posted: 26 Jan 13 at 5:39pm |

|

Countersink the holes before you screw into them, so the glass doesn't crack.

|

|

|

|

Post Reply

|

Page 12> |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

Copyright ©2001-2010 Web Wiz

Change your personal settings, or read our privacy policy

Printable Version

Printable Version Delicious

Delicious Digg

Digg Facebook

Facebook Furl

Furl Google

Google MySpace

MySpace Newsvine

Newsvine reddit

reddit StumbleUpon

StumbleUpon Twitter

Twitter Windows Live

Windows Live Yahoo Bookmarks

Yahoo Bookmarks Topic Options

Topic Options