-202403121604.gif)

-YandY-202303241230.gif)

Boats for sale

| Laurent Giles 'Jolly Boat' Exeter |

|

| J24 (Sail No. 4239) Dartmouth |

|

| Laser XD 203301 Upminster |

|

List classes of boat for sale |

’Repairing’ self-tapper holes |

Post Reply

|

| Author | |

ColH

Far too distracted from work

Joined: 11 Jan 06 Location: United Kingdom Online Status: Offline Posts: 242 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: ’Repairing’ self-tapper holes Topic: ’Repairing’ self-tapper holesPosted: 18 Feb 06 at 12:01pm |

|

I've got two holes which held a cleat with self-tappers but have lost their 'bite'. So I reckon I can drill the holes out fully and just fit bolts (75mm, if I can find M4's that long) - as long as I can get the angles just right..... Or I could try to re-cut the holes: drill out extra-large and use fibre rawlplugs (with plenty of sealant!), or fill with epoxy and re-drill & tap. Not sure how well a self-tapper will cut into epoxy, though; figure it'll need a fairly wide pilot hole. Anyone got any thoughts or alternative suggestions? Col

Edited by ColH |

|

|

|

Garry

Really should get out more

Joined: 18 Apr 04 Location: United Kingdom Online Status: Offline Posts: 536 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 Feb 06 at 11:39am Posted: 19 Feb 06 at 11:39am |

|

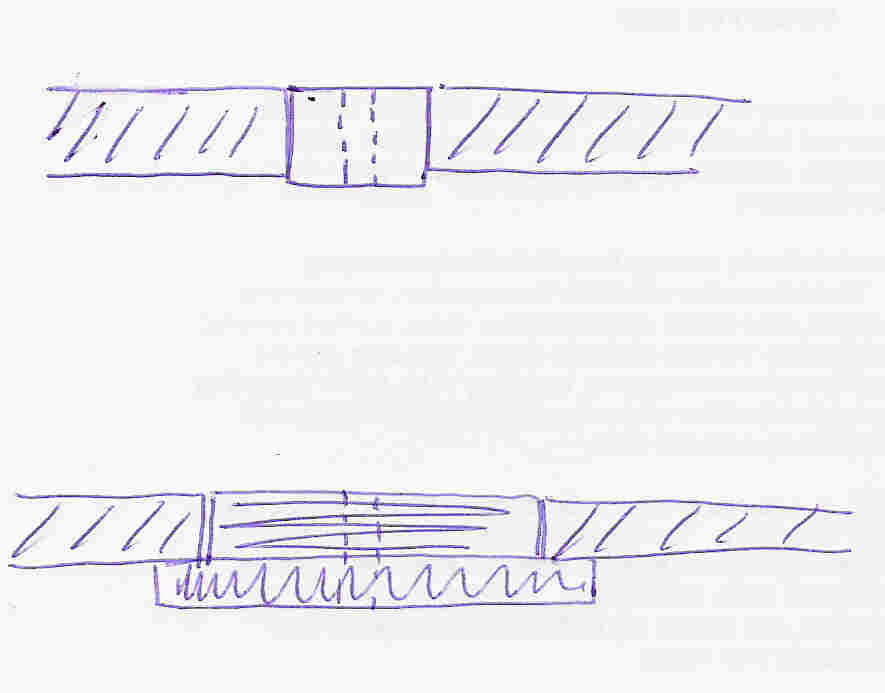

I would suggest drilling/cutting out a larger area and epoxying a hardwood plug in place. This can then either be drilled completely through and bolted or pilot drilled and self tappers used. If the wood you are drilling into is very thin you may want to cut a small rectangle out so you can fit an oversize slab of wood on teh inside then build the level up until flush.

Don't know if the attached diagrams are any help.

|

|

|

Garry

Lark 2252, Contender 298 www.cuckoos.eclipse.co.uk |

|

|

|

CurlyBen

Really should get out more

Joined: 17 Aug 05 Location: Southampton Online Status: Offline Posts: 539 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 Feb 06 at 12:36pm Posted: 19 Feb 06 at 12:36pm |

|

I had a similar problem a while ago on my Laser, the screws that hold the mainsheet block also secure the toe strap and on a windy day one pulled out! Some slow setting Araldite (stronger than the quick setting stuff) did the job well, couldn't get as much as a creak from it and no movement whatsoever. I didn't drill big pilot holes but the screws were very stiff.

|

|

|

RS800 GBR848

Weston SC |

|

|

|

Post Reply

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

Bulletin Board Software by Web Wiz Forums® version 9.665y

Copyright ©2001-2010 Web Wiz

Change your personal settings, or read our privacy policy

Copyright ©2001-2010 Web Wiz

Change your personal settings, or read our privacy policy

Printable Version

Printable Version Delicious

Delicious Digg

Digg Facebook

Facebook Furl

Furl Google

Google MySpace

MySpace Newsvine

Newsvine reddit

reddit StumbleUpon

StumbleUpon Twitter

Twitter Windows Live

Windows Live Yahoo Bookmarks

Yahoo Bookmarks Topic Options

Topic Options