Plywood Kit Designers

Printed From: Yachts and Yachting Online

Category: Dinghy classes

Forum Name: Dinghy development

Forum Discription: The latest moves in the dinghy market

URL: http://www.yachtsandyachting.com/forum/forum_posts.asp?TID=13633

Printed Date: 29 Jun 25 at 12:41am

Software Version: Web Wiz Forums 9.665y - http://www.webwizforums.com

Topic: Plywood Kit Designers

Posted By: Sid92

Subject: Plywood Kit Designers

Date Posted: 24 Jul 20 at 6:06pm

|

After many years of double handed dinghy sailing I'm looking to get a single hander due to the Covid situation.

After reviewing whats available in the market I'm struggling to find a suitable craft so am looking at the potential for a modern ply constucted design which could be made by a competent diy er. My thinking is something about 14ft capable of carrying weight with a deep ish cockpit to ensure no kneeling is required. A hiking single sail boat using a Phantom carbon mast (or similar) and a similar sail design / area to reduce development costs. The ideal design would be one with enough rocker to support inland sailing on restricted waters but still be a fast boat. Appreciate there are many designs available currently but in my mind they are all for sub 105kg sailers with the young and agile in mind. I have previously sailed Phantoms,Ok's, contenders but some time ago. The design / construction would be along the lines Leech OK project. Can anyone think of any suitable UK designers? |

Replies:

Posted By: Rupert

Date Posted: 24 Jul 20 at 6:29pm

|

Keith Callaghan designed the Hadron - take a look. It morphed into the H2

Nessa owned one will know more. ------------- Firefly 2324, Puffin 229, Minisail 3446 Mirror 70686 |

Posted By: JimC

Date Posted: 24 Jul 20 at 6:49pm

|

There are arguably two separate design challenges. The first is to get a shape, which arguably could be one of the existing classes, and the second is to generate a millimetre accurate cad/cam file to cut the ply from. The second is arguably the bigger challenge.

|

Posted By: Sid92

Date Posted: 24 Jul 20 at 6:50pm

|

Thanks Rupert I have tried an H2. Its a nice boat but for lighter helms.

I would think 12 - 13 stone is ideal for the H2 I'm looking at something comfortable for 14.5 stone helms plus..I'm at 17 stone and relatively fit but at over 6ft it needs to be more on the scale of a Megabyte which is a nice boat from a hull design point of view but again would suggest the rig is designed for lighter weights. (Also its imposible to find then for sale..) |

Posted By: Sid92

Date Posted: 24 Jul 20 at 6:58pm

| Thanks Jim, what class were you thinking? I did think something along the lines of a scaled up streaker might be similar to what I imagined although with a bit more beam or so ething like the Sabre or Impulse from Australia? |

Posted By: Rupert

Date Posted: 24 Jul 20 at 7:05pm

The original Hadron appears to have a bit more volume to it, but it may be that the designer can tweak it, or already has a design up his sleeve. Otherwise, most home build ply designers are concentrating on cruising boats. I know some big people who have owned Megabytes, certainly more than 17 stone, if they will forgive me saying. Like hens teeth though in the UK. ------------- Firefly 2324, Puffin 229, Minisail 3446 Mirror 70686 |

Posted By: Daniel Holman

Date Posted: 24 Jul 20 at 7:09pm

|

You can build a phantom from sheet ply, I know that there are glass boats with "wells" to give less than appalling downwind ergonomics, so that arrangement could be replicated in ply. Is there any reason why you wouldn't want a phant? If for whatever reason thats not cool and you don't want something completely custom, have a look at the woods designs stealth or zest: http://boatplans.cc/woods-designs/stealth/ https://www.sailingcatamarans.com/index.php/designs-2/46-beach-cats-and-dinghies/436-zest Richard Woods is the daddy at ply kit designs albeit generally on larger multihulls |

Posted By: Sid92

Date Posted: 24 Jul 20 at 7:40pm

| I enjoyed the Phantom I had but found current design to be very hard on the knees.. I like the look of the JJ deep cockpit versions but still feel there are poor ergonomics for the deep offwind work and you also have the low boom issue. |

Posted By: KazRob

Date Posted: 24 Jul 20 at 7:42pm

|

Why not speak to Dan Leech to get a design done? Maybe he could stretch the OK out a bit more into something for you (although his new Mk4 OK is aimed at ~105kg helms). He charges 600NZ$ for the OK cad files (~£300?) to get the boat and jig panels cut so it may save you time an money in the long run. For those that like something more radical than the OK, he does some other cool boats too http://www.leechboats.com/sail" rel="nofollow - http://www.leechboats.com/sail BTW - well worth getting a try in the OK class demo boat. Lots of sailors (inc me) over 6ft and 100+kg in them. Think the rig might be further forward and more upright than you maybe tried before.

------------- OK 2249 D-1 138 |

Posted By: CapSizer

Date Posted: 24 Jul 20 at 7:44pm

| Why is a single-floor ply Phantom out of the question? |

Posted By: Sid92

Date Posted: 24 Jul 20 at 8:03pm

| Good point, have not seen an older Phant up close to see if there is a suitable place to perch. Guess the deeper floor also helps with the boom height! |

Posted By: Sid92

Date Posted: 24 Jul 20 at 8:04pm

| Remember not having to kneal in the OK but is a 34" unside leg ok re toe strap position? |

Posted By: Neal_g

Date Posted: 24 Jul 20 at 8:08pm

|

There was a guy at our club in kent who had a phantom wooden lightweight which needed a repaint and bailers sorting not sure if he still has it ------------- (Redoubt Sc) Miracle 4040 GP14 13407 Crewsaver phase 2 range now available to buy online on at http://www.gibsonsails.com |

Posted By: KazRob

Date Posted: 24 Jul 20 at 8:22pm

Nick Craig, Freddy Loof and a few others aren't short on leg length. Have a look at this pic of Nick http://www.flickr.com/photos/okdia/34591545700/in/album-72157681350512684/" rel="nofollow - http://www.flickr.com/photos/okdia/34591545700/in/album-72157681350512684/ And Ben must be over 6.5ft! http://www.facebook.com/191031244256913/photos/a.826233550736676/3039956509364358/?type=3&theater" rel="nofollow - http://www.facebook.com/191031244256913/photos/a.826233550736676/3039956509364358/?type=3&theater Get hold of the demo boat for a try - there's nothing to lose trying and if you like it get a Leech kitboat ------------- OK 2249 D-1 138 |

Posted By: Sid92

Date Posted: 24 Jul 20 at 8:27pm

| Thanks for the info / pics. Will have another look |

Posted By: Late starter

Date Posted: 27 Jul 20 at 8:52am

| I sailed an old single floor (ie deep cockpit) Phantom back in the day. Nice boat, reasonably roomy and with plenty of space to "perch". I believe many of these early boats were built from kits, though I'm not sure if there are any kit suppliers around any more. However, much as I liked my old boat it was totally outclassed in terms of performance by the double floor epoxy/carbon ships that represent most of the fleet nowadays. If you're sailing for fun, fine, but for racing I think you'd be 50 PY points slower than a modern Phantom. And building this isn't going to be cheap and I doubt if it would have much re-sale value. But they were nice boats to sail, and if racing and money isn't an issue go for it ! |

Posted By: Riv

Date Posted: 28 Jul 20 at 11:26am

|

The OK can be built out of wood and be competative against foam sandwich boats. What is different about the Phantom that makes this not possible? ------------- Mistral Div II prototype board, Original Windsurfer, Hornet built'74. |

Posted By: Cirrus

Date Posted: 28 Jul 20 at 11:45am

|

What is different about the Phantom that makes this not possible? Almost certainly 'compound curves' - the Phant had a lot of freedom to allow self builders to stay within the rules building in their garages - later this was 'used' to build in compound curves into the later composite hulls... and the plywood boats started to struggle ... I would assume the OK has a much tigher measurement policy.

|

Posted By: KazRob

Date Posted: 28 Jul 20 at 12:32pm

|

I'm not sure but I think the tolerances are +/-10mm at the measurement points so there is quite a variation in shape and panel curvature between designs (but they all seem to go about the same tbh). The Leech method just uses modern technology to get a millimeter perfect jig locked together before the similarly accurate panels are offered up to it. Much more accurate than the old hand cut / stich and glue method and I don't see why other classes couldn't do the same. Plywood is a really stiff and sustainable material to build boats from after all. ------------- OK 2249 D-1 138 |

Posted By: Gordon 1430

Date Posted: 28 Jul 20 at 12:35pm

|

Hi Mike The Phantom mould was taken from a fast wooden boat so no need for a slow hull shape. Building the hull of ply it was a problem to keep it within weight John Claridge did build some fast lovely double bottom boats and knowing John down to weight. I think the woodies in the fleet are using either tin or early carbon rigs not the current rigs of choice. Think that makes a big difference as well. With laser cutting a Kit would be an option, I wonder what the cost of good marine ply would be in comparison with a hull from Ovington. ------------- Gordon Phantom 1430 |

Posted By: KazRob

Date Posted: 28 Jul 20 at 1:28pm

|

I'm not sure about the Phantom but the info I have from Dan Leech is ~£300 for the CAD files, 4 sheets of 18mm (good grade plywood for the jig), 4 sheets of 6mm Gaboon and 4 sheets of 4mm Gaboon marine plywood for the boat. Build time is around 60hours. So I'm guessing about £1-2k to build the boat ready to fit out ------------- OK 2249 D-1 138 |

Posted By: maxibuddah

Date Posted: 28 Jul 20 at 2:27pm

you forgot the extra gallon or so of epoxy and extra sheets of ply when you somehow manage to screw up the simple putting it together part  Plus the painting of course. ------------- Everything I say is my opinion, honest |

Posted By: Noah

Date Posted: 28 Jul 20 at 3:30pm

|

I may be mistaken but I seem to recall some Merlins being built from a ply / foam / ply sandwich. Whether this would work on bigger panels as it does (unless my memory is playing tricks again) on a clinker plank I don't know. Cost is no doubt higher, too. There's also the rules adherence issue... ------------- Nick D-Zero 316 |

Posted By: KazRob

Date Posted: 28 Jul 20 at 4:00pm

|

Dave Rose used to build OKs in ply/foam/ply sandwich and they are super stiff by all accounts. They last forever too with a ~30yr old one getting 3rd in the Europeans a few years back I seem to remember. ------------- OK 2249 D-1 138 |

Posted By: Sam.Spoons

Date Posted: 28 Jul 20 at 4:23pm

|

The OK is 11kg heavier, 42cm shorter and 39cm narrower than a Phantom. It has 3 full size bulkheads dividing the hull into four compartments*, and incidentally adding considerable rigidity and strength. The Phantom OTOH is substantially open with narrow side decks all the way from the mast to the transom which is going to lead to a less rigid structure. * The basic principle is much the same as a box girder bridge, admittedly the Phantom has it's double bottom to add rigidity but it is never going to be as stiff as the full height box sections of the OK. ------------- Spice 346 "Flat Broke" Blaze 671 "supersonic soap dish" |

Posted By: tink

Date Posted: 28 Jul 20 at 4:59pm

Not sure about 60hrs, watched the video, lots more than 60hrs ------------- Tink https://tinkboats.com http://proasail.blogspot.com |

Posted By: KazRob

Date Posted: 28 Jul 20 at 5:12pm

60hrs is what Dan Leech told me it takes the average builder when I was as asking him about the kit set a few weeks ago. ------------- OK 2249 D-1 138 |

Posted By: Riv

Date Posted: 28 Jul 20 at 8:01pm

|

So Woodie Phantoms are heavier, less torsionally stiff, may not have compound curves, are using older rig and not double bottomed so may carry water. Given the success of the OK plwood format could these problems be designed out if class rules were relaxed in some areas for wood boats? ------------- Mistral Div II prototype board, Original Windsurfer, Hornet built'74. |

Posted By: JimC

Date Posted: 28 Jul 20 at 9:07pm

| If plywood OKs are completely equal in performance to foam sandwich boats then that's surprising. Bearing in mind the far greater panel stiffness of foam boats it does seem unlikely. I certainly don't know of another class where its the case. |

Posted By: Rupert

Date Posted: 28 Jul 20 at 9:12pm

|

Sam Spoons' thoughts could go some way to explaining why,Jim. ------------- Firefly 2324, Puffin 229, Minisail 3446 Mirror 70686 |

Posted By: Cirrus

Date Posted: 28 Jul 20 at 9:48pm

|

If you have a class that already has compound curves available via the composite route it still does not matter how tight you then set the measurement rules .. whatever the rules or wording you simply cannot make ply bend to match the compound curves that are very straightforward in an optimised FRP composite. 'Modern' phantoms will always be faster as they are simply better shaped than can ever be achieved via bending and twisting 8x4 ply sheets. You cannot copy the compound curved shaping. Look at all the other traditional, originally plywood and chine, classes that made the transition down the years (with the possibly partial exception of the OK granted) - the ply build has died on its knees as a competitive or worthwhile build route. |

Posted By: Gordon 1430

Date Posted: 29 Jul 20 at 6:15am

|

Cirrus as per ,y previous post all epoxy Phantoms hulls come from a mould taken of a wooden boat. so don't se where the comment about compound curves come in. Hasn't a Magnum moth hull got compound curves? They were built from ply. ------------- Gordon Phantom 1430 |

Posted By: Riv

Date Posted: 29 Jul 20 at 6:19am

|

So, no matter how stiff torsionally a dinghy hull shell can be made the weight distribution being the same and down to minimum weight the ability to increase the volume of the hull with the least increase in wetted area is the most important factor in a fast boat assuming all other tolerances have been exploited?

------------- Mistral Div II prototype board, Original Windsurfer, Hornet built'74. |

Posted By: salmon80

Date Posted: 29 Jul 20 at 6:26am

3mm ply.......

|

Posted By: CapSizer

Date Posted: 29 Jul 20 at 6:43am

|

For those not imtimately familiar with old-style plywood Phantoms, even the the standard old stitch and glue ones had more panel curvature than you might think. The bottom edge on both the main and transom bulkheads had quite a bit of curvature, so it is not the slab shape that it appears to be. The way that the bow is developed introduces a lot of local curvature into the panel, and it actually required some force to pull the boat into shape over the main bulkhead. None of this is compound curvature, of course. With regards to why a wooden OK can still be competitive and a wooden Phantom not, I would suggest that a wooden OK, given the size, mass and panel sizes, can be made "very" stiff. Probably stiff enough, if not as stiff as a composite one. A wooden Phantom at minimum allowed mass has large panels with minimal support, so it is easy to see why it cannot be anywhere near as stiff as a well-engineered epoxy sandwich boat. Having said that, it is not immediately obvious why a less stiff boat should necessarily be that much slower. It is not as if you are trying to control jib luff sag with rig tension.

|

Posted By: Noah

Date Posted: 29 Jul 20 at 7:19am

|

Do I recall that someone aeons ago tried to make the venerable Finn much more rigid and it turned out to be dog slow? Why would that be? ------------- Nick D-Zero 316 |

Posted By: KazRob

Date Posted: 29 Jul 20 at 7:37am

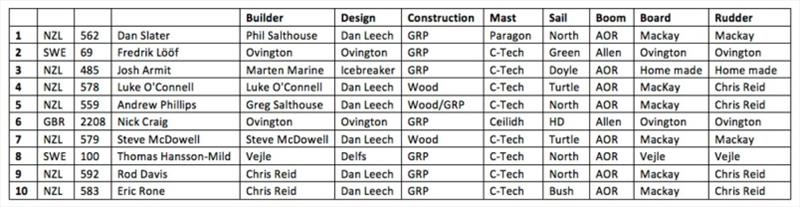

Jim it is indeed the case that wood boats are as fast as foam sandwich ones in the OK. It is probably for all the reasons above but it is encouraging to see that this is a possible route again now we are all supposed to be more careful about sustainability etc. The table below is from the last Worlds in early 2019 taken from ( https://www.yachtsandyachting.com/news/215612/Individualistic-choice-of-OK-Dinghy-Equipment" rel="nofollow - https://www.yachtsandyachting.com/news/215612/Individualistic-choice-of-OK-Dinghy-Equipment ). The article also sys that only four of the top ten were production boats, the rest being either home built, or built using Dan Leech's CNC kitset plans by professional builders and the third placed boat in Auckland was 35-years old Icebreaker.  ------------- OK 2249 D-1 138 |

Posted By: mongrel

Date Posted: 29 Jul 20 at 7:48am

Er Contender?

|

Posted By: Bootscooter

Date Posted: 29 Jul 20 at 8:27am

My understanding is that it's to do with the flexing relationship between the centreboard, hull and unstayed rig - the twist in the hull allows for 'flick'and extra energy transfer into the rig in wavy and pumping conditions. Aside from at Olympic level where the nth degree of performance is being chased, this is thought to be why (along with the strength and build quality afforded by being so heavy) 20+ year old hulls can still be competitive in National Masters fleets if they're well looked after. ------------- |

Posted By: andy h

Date Posted: 29 Jul 20 at 9:40am

|

I thought with Merlins you could only build an FRP one with tooling taken off a fully sailable measured wooden hull. Granted they are clinker rather than hard chine. Do any other classes have that rule? ------------- Europe AUS53 & FF 3615 National 12 3344, Europe 397 and Mirror 53962 all gone with regret |

Posted By: Noah

Date Posted: 29 Jul 20 at 10:27am

Not sure what the contender reference is intended to mean, but the wooden boats are cold moulded, aren't they - not ply. AFAIK Signore Bonezzi(?) in Italy still builds beautiful hulls but I bet they are eye-wateringly expensive. ------------- Nick D-Zero 316 |

Posted By: JimC

Date Posted: 29 Jul 20 at 10:59am

|

With judgement, skill and appropriate use of brute force you can get a fair amount of 3 dimensional curvature in ply, and even more if you build the required area from two layers of thin ply rather than one layer of thick. Back in the day it was even by no means unknown to cold mould a small area where extreme 3D curvature was required and do the rest of the boat in ply.

But the shape of a Phantom, with large flat panels means that foam sandwich with better panel stiffness is going to be superior, and there's really no way round that. One only has to look at the way the Phantom PY plummmeted once foam sandwich hulls and carbon spars were widespread in the fleet. However you can get too excited about boat speed if one is not a front of fleet sailor. Is it really more fun to be racing for 10th place rather than 15th? I suggest that if you are out on the water enjoying competitive sailing with congenial people then the job is done. |

Posted By: KazRob

Date Posted: 29 Jul 20 at 11:05am

+1 from me on that sentiment  ------------- OK 2249 D-1 138 |

Posted By: mongrel

Date Posted: 29 Jul 20 at 11:17am

Wooden Bonezzis’ were plywood, still very sought after, as quick/quicker than the FRPs’.

|

Posted By: maxibuddah

Date Posted: 29 Jul 20 at 12:52pm

most of the reason why the PY plummetted was down to the epoxy boats being up to 14 kgs lighter than the GRP and even more on some wooden boats. The carbon spars did not make that much difference in the earlier days other than perhaps the helms not being knocked so much. ------------- Everything I say is my opinion, honest |

Posted By: Riv

Date Posted: 29 Jul 20 at 1:19pm

|

So, fast for most boats is stiff panels and high resistance to twisting assuming optimum weight and weight distribution

------------- Mistral Div II prototype board, Original Windsurfer, Hornet built'74. |

Posted By: JimC

Date Posted: 29 Jul 20 at 3:25pm

Doesn't explain why similar PY changes have been seen on just about every other class that's adopted foam sandwich. |

Posted By: Cirrus

Date Posted: 29 Jul 20 at 3:40pm

|

....all epoxy Phantoms hulls come from a mould taken of a wooden boat. Not from the mouth of one of the 'developers' of the Phantom epoxy hulls I have spoken with on the subject ! .... besides don't believe me just put a rigid steel rule across a epoxy modern hull and see for yourself.... They did not all come from a mythical single ancestor without some subtle but still significant ... eer 'tweaking' along the way !! Why would you not tweak the plug and tooling to real competitive advantage when the set tolerence rules allowed a medium sized bus to be driven through them and you were changing materials anyway (and therefore also changing the limitations imposed by the materials involved). You can bend ply and you can also twist it but if you effectively get into cold moulding it, as has already been said, it is not really regular plywood anymore and that really is the only way to get a compound curve into a multi-layer wood shape ... And frankly if it was even practical in a formal production sense it would still be more efficient to build in foam and epoxy imo if allowed - so why do it ? And as goes with the Phantom you can add many other classes to the same list of those suitable to be 'tweaked' when a switch to moulding went through - Solo, Fireball, Enterprise etc spring immediately to mind and you will think of others I'm sure (though lets agree maybe not as completely with the OK maybe !)

|

Posted By: tink

Date Posted: 29 Jul 20 at 6:36pm

|

Interesting stuff, the classic theory is that ply can be bent into a conic form (this has been stretched slightly to tortured or compound bending). Draw two diverging lines on a piece of paper, bend it normal to axis of symmetry of the two lines and it easy to see what ply is capable of. Jump 50+ years ahead and two things have changed: fast hull shapes are very different and we have CAD that could create a stiff multiple panel (not necessarily chines) hull shapes made of stiff conical ply forms. All very hypothetical as development cost would out weigh the number of people prepared to take the risk and spend the time actually building the resulting boat. All a UK perspective though, lively home built Proa scene in Poland because it the most boat you get from the least materials. ------------- Tink https://tinkboats.com http://proasail.blogspot.com |

Posted By: Noah

Date Posted: 29 Jul 20 at 6:38pm

Well I never knew that. Always thought they were built from summat exotic. I stand corrected. ------------- Nick D-Zero 316 |

Posted By: tink

Date Posted: 29 Jul 20 at 6:54pm

I think that is an anomaly. My cold moulded IC was no comparison to the epoxy carbon foam sandwich one that replaced it. ------------- Tink https://tinkboats.com http://proasail.blogspot.com |

Posted By: CapSizer

Date Posted: 29 Jul 20 at 7:12pm

Well, isn't the Contender known to be quite heavy? So if the weight limit is high, it makes sense that wood can be reasonably competitive, witness Contender and OK. Whereas if the limit is low, as with the Phantom, wood cannot really compete.

|

Posted By: tink

Date Posted: 29 Jul 20 at 7:26pm

+1 that’s the death of ply boats in a nut shell. Newer boats designed with a 10kg lower weight for questionably small increase in performance but enough to make GRP boat building profitable and obsolete lots of great wooden boats.

------------- Tink https://tinkboats.com http://proasail.blogspot.com |

Posted By: maxibuddah

Date Posted: 29 Jul 20 at 8:37pm

but in the Phantom's case the boat was already designed to be 61kgs but it was rare that any wooden boats actually got near it (Claridges apart). The GRP boats didn't on the whole either but they enabled owners to have relatively maintenence free sailing. As for Jim's comment about the frp/grp boats etc, well all of the early epoxy boats came from the same mould as the polyester boats so the performance gain must have come from the weight or stiffness gains (assuming there were some). I certainly know that when I moved from a poly boat to an epoxy one it was like a different class, so much more responsive, in fact too much and I fell in backwards on a reach. My epoxy boat had 1.5kgs cof correctors too so a massive overall difference to the old boat. I was still using a tin rig at the time and it didn't slow me down overall. ------------- Everything I say is my opinion, honest |

Posted By: Sam.Spoons

Date Posted: 30 Jul 20 at 9:30am

Bonezzi Contenders are cold moulded in wood using epoxy resin infusion techniques. I suspect if you told Mr Bonezzi his boats were made from plywood he would be quite upset  ------------- Spice 346 "Flat Broke" Blaze 671 "supersonic soap dish" |

Posted By: JimC

Date Posted: 30 Jul 20 at 9:49am

| If one wishes to be pedantic (and this is the internet [grin]) moulding from veneers is simply the process of creating curved plywood on the mould... |

Posted By: CapSizer

Date Posted: 30 Jul 20 at 10:01am

It's plywood, Jim, but not as we know it! |

Posted By: mongrel

Date Posted: 30 Jul 20 at 11:07am

I’d agree with that, that the conservative weight limit of the Contender and OK allow wooden construction to remain competitive, also as mentioned earlier, the shape of the OK being quite boxy promotes quite a stiff structure.

|

Posted By: Sam.Spoons

Date Posted: 30 Jul 20 at 11:42am

I still think that going up to the bloke with the shiny new Bonezzi Contender and saying "how are you liking your plywood boat?" is asking for a knuckle sandwich

------------- Spice 346 "Flat Broke" Blaze 671 "supersonic soap dish" |

Posted By: Sam.Spoons

Date Posted: 30 Jul 20 at 11:54am

|

Right, definitive answer, according to the CED Plywood is "wood in sheets that is made of several thin layers glues together" so a cold moulded boat is not made of 'plywood' ('cos it's not in sheets). Unfortunately for this argument the OED says "A type of strong thin wooden board consisting of two or more layers glued and pressed together with the direction of the grain alternating." which is slightly less definitive thou "a type of strong thin wooden board" does imply that the material starts out as flat. But what do we dinghy bods know anyway, we can't even decide what FRP stands for....  ------------- Spice 346 "Flat Broke" Blaze 671 "supersonic soap dish" |

Posted By: maxibuddah

Date Posted: 30 Jul 20 at 2:59pm

thats easy, F****** Really Pricey

------------- Everything I say is my opinion, honest |

Posted By: Rupert

Date Posted: 30 Jul 20 at 6:15pm

|

Fantasy Role Playing? ------------- Firefly 2324, Puffin 229, Minisail 3446 Mirror 70686 |

Posted By: tink

Date Posted: 30 Jul 20 at 6:38pm

|

Fantastically Rigid Ply ------------- Tink https://tinkboats.com http://proasail.blogspot.com |