-202403121604.gif)

| Laser XD 203301 Upminster |

|

| Laurent Giles 'Jolly Boat' Exeter |

|

| J24 (Sail No. 4239) Dartmouth |

|

List classes of boat for sale |

RS 600 Daggerboard |

Post Reply

|

| Author | |

600sailor670

Newbie

Joined: 07 Nov 07 Location: United Kingdom Online Status: Offline Posts: 24 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: RS 600 Daggerboard Topic: RS 600 DaggerboardPosted: 04 Dec 08 at 5:39pm |

|

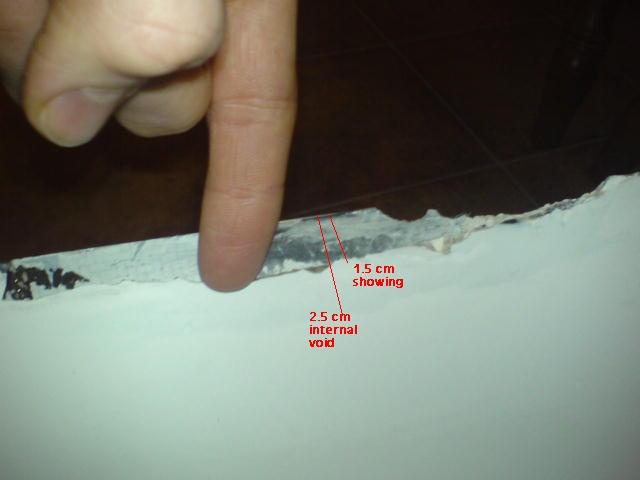

Hi everyone Managed to take a large chunk out of the trailing edge of my 600 daggerboard last weekend and was wondering how best to repair it. I think the construction is polyster resin, althought if anyone could confirm that, that would be great. I could do with advice on what the correct materials to use for this are and how best to strengthen the area (e.g. put metal pins in, add fibres to the resin etc). It seems the foil is constructed from two halves and bonded with resin with a foam core, and the majority of the broken part is one half of the trailing edge and a large chunk of internal material(as shown in pic two "the void area"). (so there is still one side of glass fibre and resin). I need to be able to build this repair up again and it be strong enough to be stood upon when capsized and also not be knocked out easily, therefore it has to be done with the correct materials and not a botch job. Any advice would be much appreicated, Many thanks George Here are some pics

|

|

|

RS600-670

RS600FF - 793 |

|

|

|

Stevie_GTI

Posting king

Joined: 21 Oct 08 Online Status: Offline Posts: 134 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 Dec 08 at 6:21pm Posted: 04 Dec 08 at 6:21pm |

|

where abouts are you based?

|

|

|

|

600sailor670

Newbie

Joined: 07 Nov 07 Location: United Kingdom Online Status: Offline Posts: 24 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 Dec 08 at 6:29pm Posted: 04 Dec 08 at 6:29pm |

|

Midlands Northamptonshire

|

|

|

RS600-670

RS600FF - 793 |

|

|

|

radixon

Really should get out more

Joined: 27 Oct 06 Location: United Kingdom Online Status: Offline Posts: 2407 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 Dec 08 at 6:32pm Posted: 04 Dec 08 at 6:32pm |

|

Ouch!

I am no expert. knocked a chunk off my Laser one, but cos I had the other bit managed to glue it back together but used pins as I had two bits. |

|

|

|

theycallmegod

Far too distracted from work

Joined: 27 Nov 07 Location: England Online Status: Offline Posts: 262 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 Dec 08 at 7:50pm Posted: 04 Dec 08 at 7:50pm |

|

B14 daggerboards are made out of different stuff, but this thread might still be useful...

|

|

|

B14 698

Laser 135776 |

|

|

|

Stevie_GTI

Posting king

Joined: 21 Oct 08 Online Status: Offline Posts: 134 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 Dec 08 at 8:18pm Posted: 04 Dec 08 at 8:18pm |

|

im assuming your sail number is 670, and the board is the original from the boat??the solution on the linked thread is ok, but i would do it a different way. Do you want the repair to be invisible after its done? will try and find out if the board is polyester or epoxy first tho |

|

|

|

Ian29937

Far too distracted from work

Joined: 25 May 05 Online Status: Offline Posts: 409 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 Dec 08 at 11:06pm Posted: 04 Dec 08 at 11:06pm |

|

If you're a member of the association, Pete Vincent did a neat piece on repairing RS boards in the association magazine a little while ago. Alternatively have you spoken to the class association or RS? You don't have to be an association member to join the RS600 Yahoo group (forum) and I'm sure they'll help. Cheers Ian |

|

|

|

craiggo

Really should get out more

Joined: 01 Apr 04 Location: United Kingdom Online Status: Offline Posts: 1810 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 05 Dec 08 at 8:18am Posted: 05 Dec 08 at 8:18am |

|

The easiest way I have found to repair RS foils is to first cut out any loose material then lightly abrade the area. On one side of the foil stick some tape down over the area that your trying to rebuild (pull it taught as you press it down), this will hopefully allo you to maintain the shape in the repaired area without having to sand to much excess off.

Mix up some West Epoxy with a generous amount of colloidal silica until its a thick paste then slap it into the area your building back up. If the area is very large its sometimes best to build it up in layers. Anyway once you have it fully filled its just a case of getting out the wet and dry and finishing to a good finish , I find that a final polish with 900grit paper gives a good enough finish. If you dont mind the fact that the repair is visible then its done, or if you want to paint it you'll need to rebuild the repair slightly undersize 0.5mm to allow for paint/gelcoat. Paul |

|

|

|

Ian29937

Far too distracted from work

Joined: 25 May 05 Online Status: Offline Posts: 409 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 05 Dec 08 at 9:40am Posted: 05 Dec 08 at 9:40am |

|

I do pretty much the same with one additional step for large dents where the damage has extended past the gel coat and damaged the glass layer. In these situations I'll incorporate a piece of glass tape in an initial layer. Doesn't look great but does the job. Cheers Ian

|

|

|

|

Rupert

Really should get out more

Joined: 11 Aug 04 Location: Whitefriars sc Online Status: Offline Posts: 8956 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 05 Dec 08 at 12:27pm Posted: 05 Dec 08 at 12:27pm |

|

If the foils are true white, a good way of hiding the repair is to use car primer spray paint, blending the edge of the spray area. Once this has been rubbed down with 1200 grit, is is very difficult to see the difference.

|

|

|

Firefly 2324, Puffin 229, Minisail 3446 Mirror 70686

|

|

|

|

Post Reply

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

Copyright ©2001-2010 Web Wiz

Change your personal settings, or read our privacy policy

Printable Version

Printable Version Delicious

Delicious Digg

Digg Facebook

Facebook Furl

Furl Google

Google MySpace

MySpace Newsvine

Newsvine reddit

reddit StumbleUpon

StumbleUpon Twitter

Twitter Windows Live

Windows Live Yahoo Bookmarks

Yahoo Bookmarks Topic Options

Topic Options